dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Bought myself this kit for the engine, already have the timing part but can sell that on and for £65 it's just handy to have

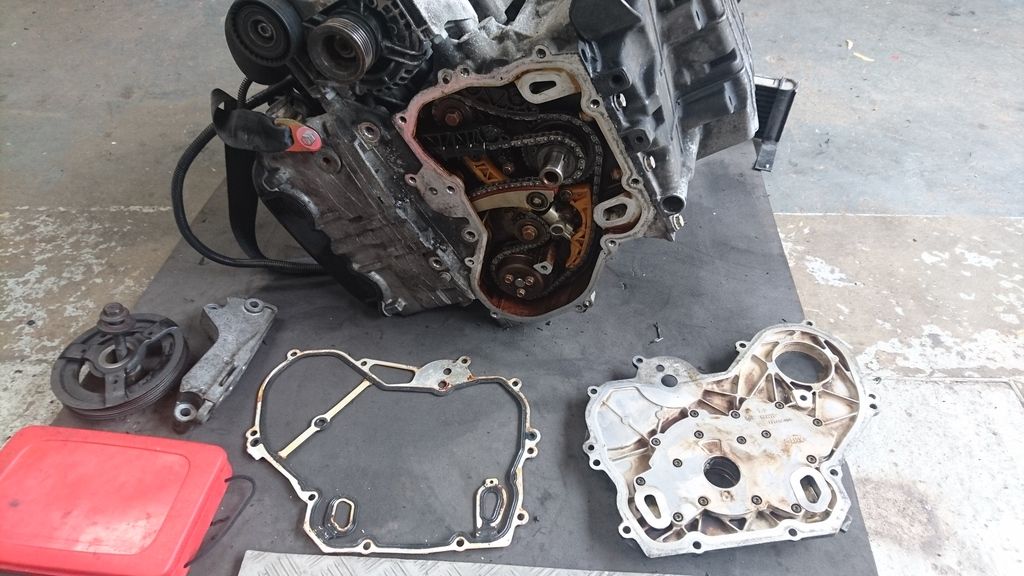

So first job was to use it to replace the leaking water pump, this one came with a metal impeller so that's a bonus

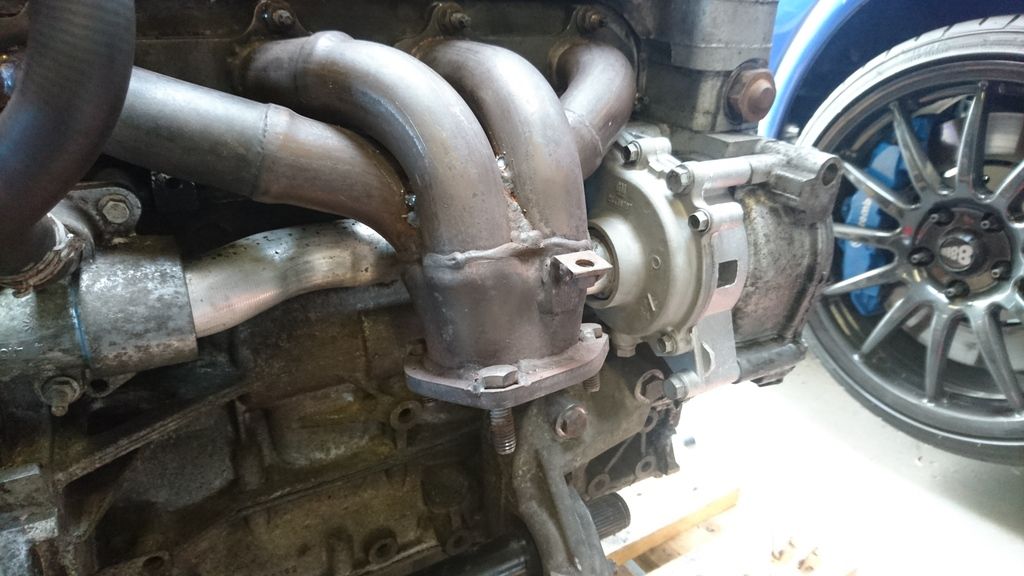

Fitted all new seals and O rings on the pipes. Re welded the leaking piper manifold again. Also replaced the rocker cover gasket when re fitting the cover as that was also leaking/sweating power.

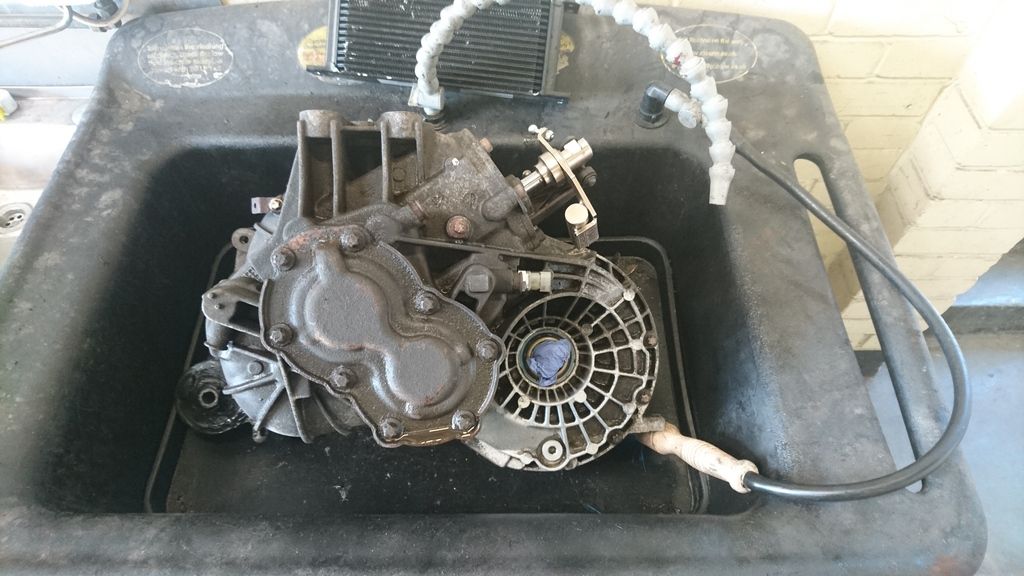

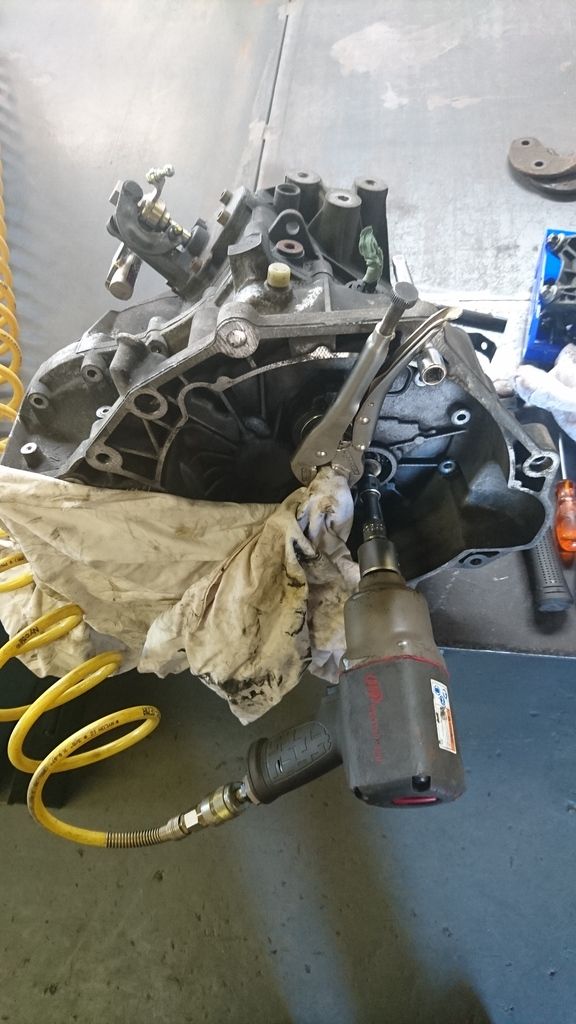

Removed gearbox and gave it a degrease and then into the parts washer

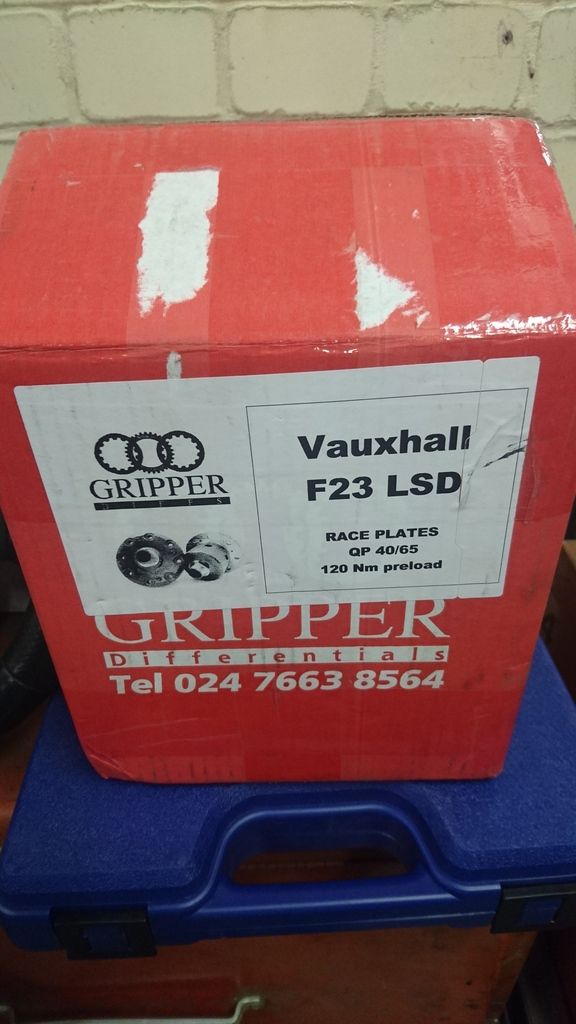

Also had a nice delivery from Gripper, just waiting on the new bearings, seals etc to turn up and I'll get cracking with fitting that. Big thanks to steveboyslim for getting me a great deal on it.

|

chris_uk

Premium Member

Registered: 8th Jul 03

Registered: 8th Jul 03

User status: Offline

|

1/2" to 3/4" adaptor needed for that kit

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

quote:

Originally posted by chris_uk

1/2" to 3/4" adaptor needed for that kit

Yeah got one already thankfully

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Fitted the C20LET helix 4 paddle clutch I kept from the corsa, should stop me over heating the clutch now on track.

The MSA are changing the rules for next year so I now need 4 tow straps one at each corner, these have a breaking strain of 2.6 ton

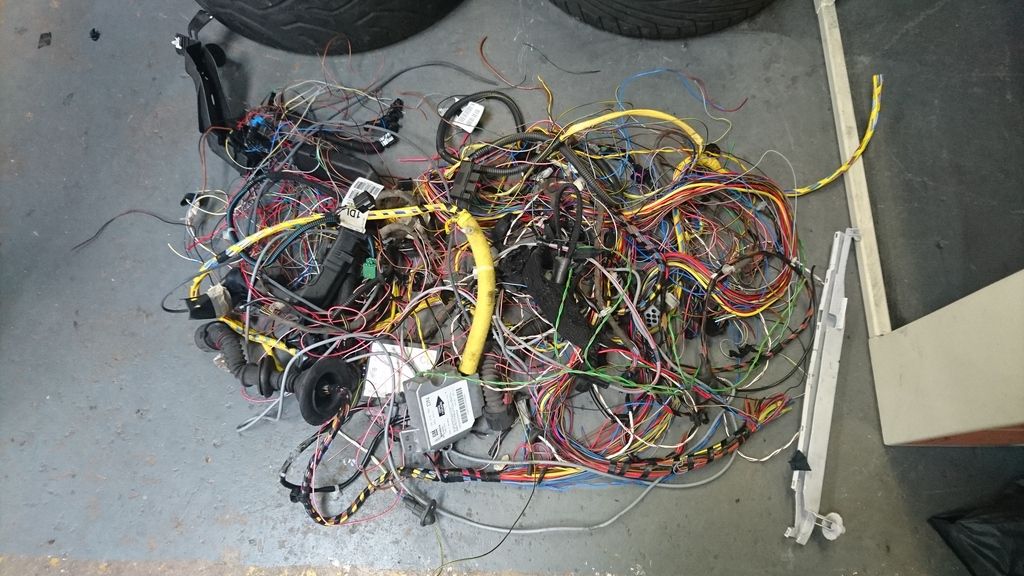

Big thanks to my mate Rob Twitchell who came over to help strip the loom down of all the non essentials

Tested functions still worked and ecu's could be read

All the non essentials removed

Saved myself 5.5kg in the process

All roughly taped up for now but looks loads better

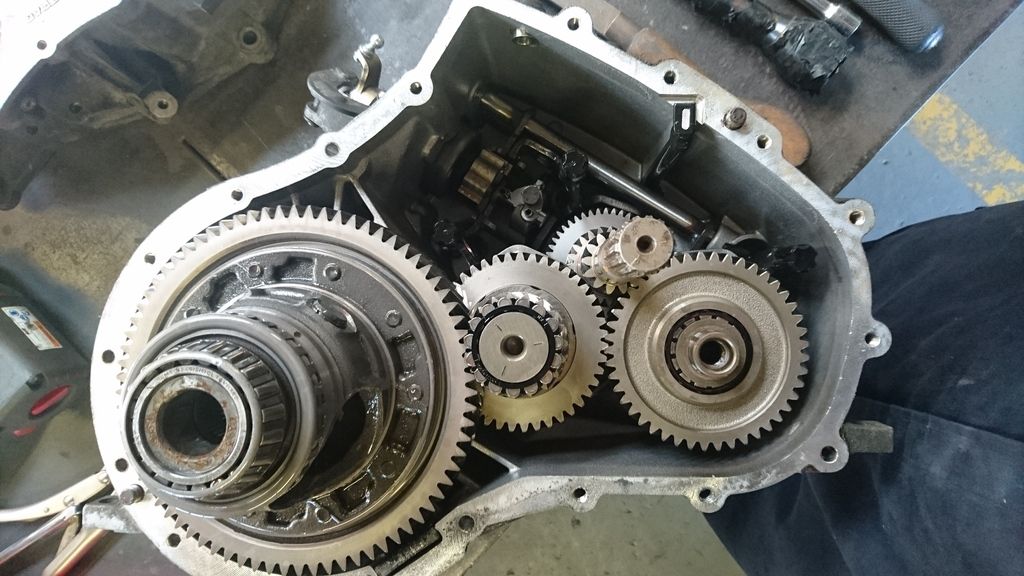

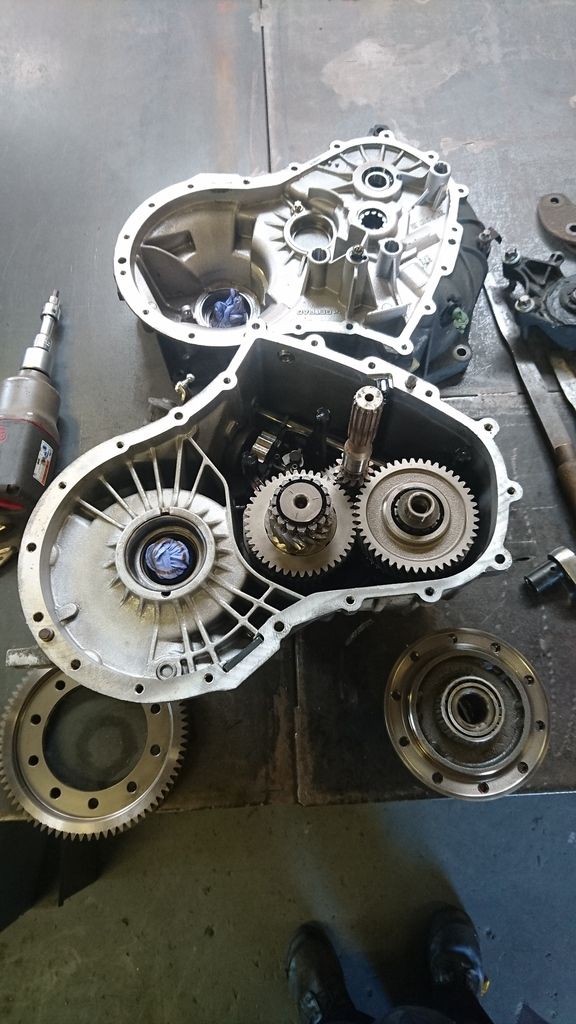

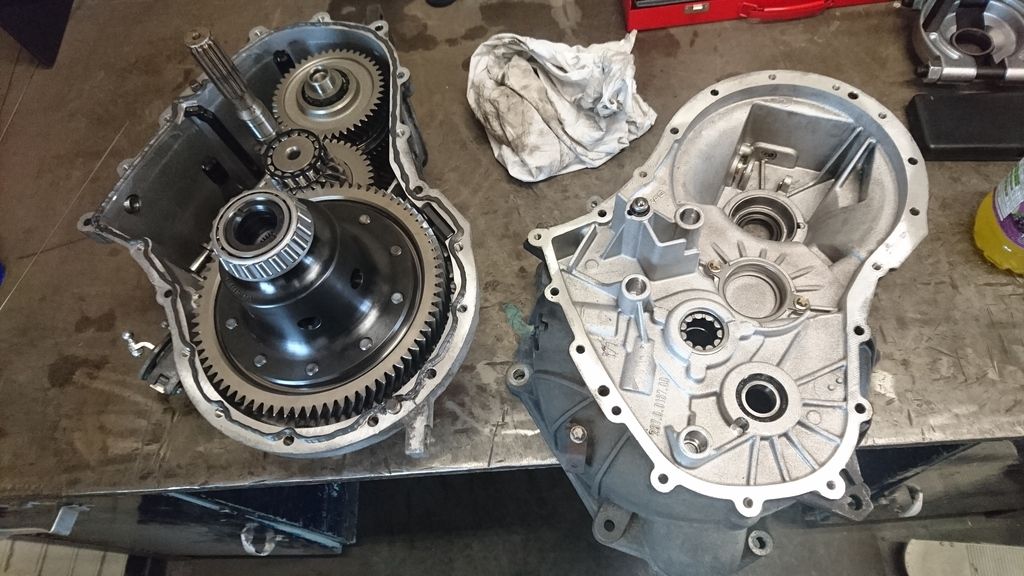

Got started on the gearbox, removed the 19 outer bolts, then picked the seal out and got the windy gun on it after I'd locked the input shaft off

Case tapped off

Diff and crown wheel removed, and gave the magnet a clean up. Just waiting on new bearings to turn up and then it can all go back together.

|

anthcorsa

Member

Registered: 18th May 07

Location: Middlesbrough

User status: Offline

|

Couldn't think of a worse task than going through that loom lol, looks a million times tidier, great progress mate.

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Yeah it was a awful job chasing wires, thankfully my mate Rob is all over stuff like that.

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Fitted all new cv joints, running the better design saab outers

Whipped the sump off and side cover as they were leaking oil so re sealed both, so hoping now i will be fully leak free

Also did my first cage test bend to see what the curve radius is. Pipe bender gives a really nice clean bend so really happy with that

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

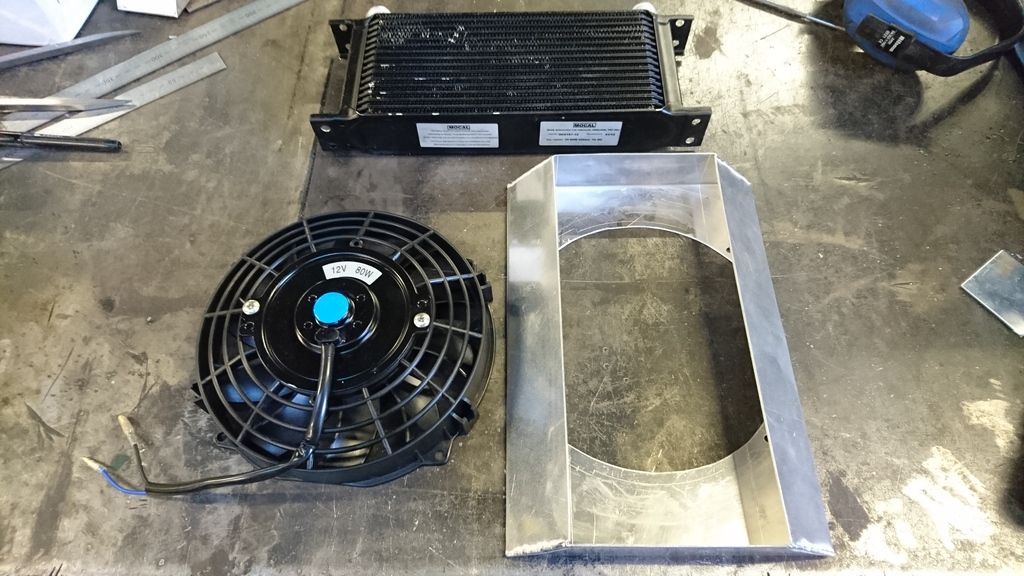

Decided to make myself a race heater/windscreen/side window de mister.

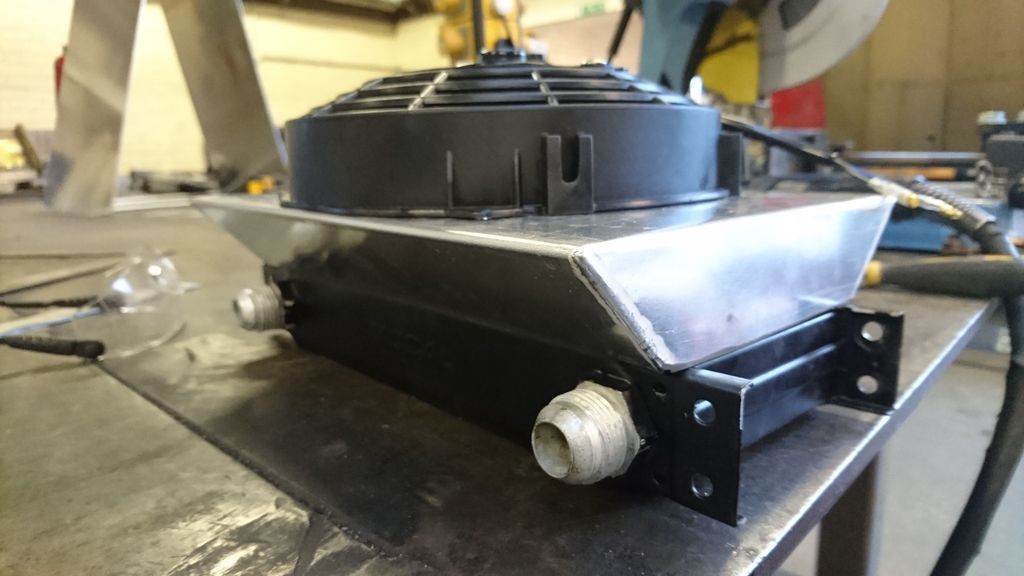

A friend gave me mocal 14 row oil cooler so gave it a good wash out in the parts de greaser and set about making a cowling to reduce from a 7" fan down to meet it

Tigged it up and will make some tabs to mount to the original brackets and then silicone around it to seal that side.

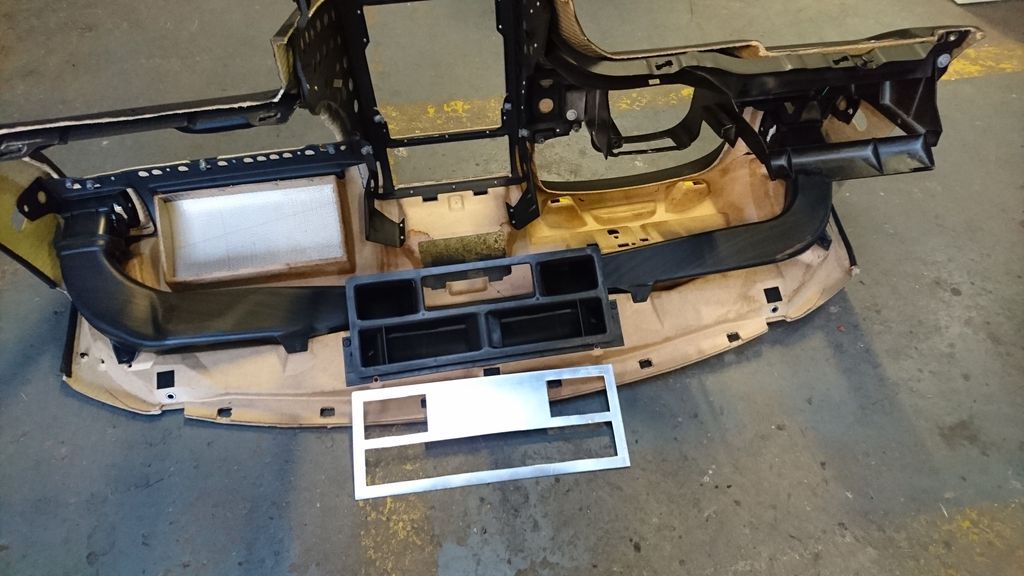

I made sure I kept the original ducting on the dash so made a blanking plate that will get riveted on once I've made another reducer for the other side.

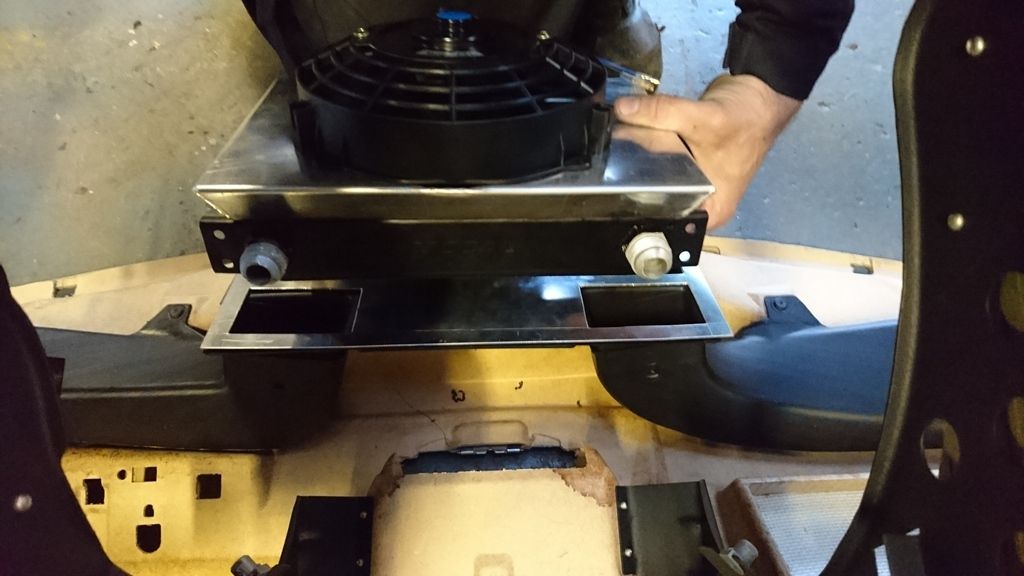

Once that's made it will sit something like this:

That'll allow me to have switchable side window vents or just all on screen to de mist. Once fitted I just need some aeroquip fittings to then run from the top of the cooler and through the bulk head and into the original water matrix pipes.

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Had my relayed electrical cut offs turn up as I doubt the ecu etc will like being instantly cut off.

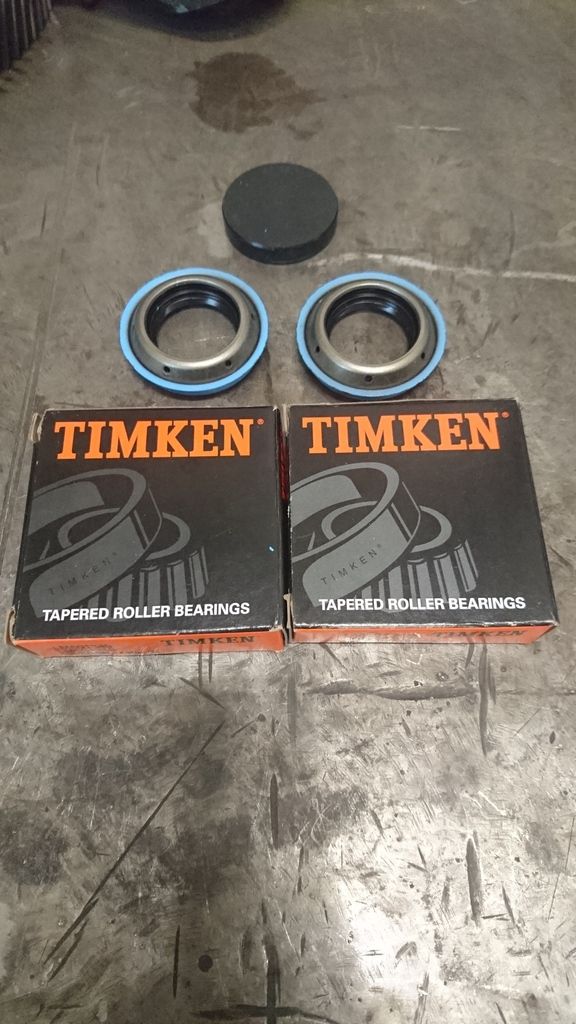

New bearings and seals turned up

Ground down a old allen key to use as tool to remove the bearing outers, fits under the bearing in the two oil gaps and knocked up with a hammer

Whipped the old bearings off to retrieve the shims underneath

Fitted shims and pressed new bearings on

Fitted crown wheel and torqued the bolts up and line marked them

Fitted diff, first gearbox must have got damaged on the gear selector or fork as once bolted up wouldn't spin the diff so after much swearing and head scratching I used the spare box and all went together with no dramas. So at some point I will re investigate that box and check all alignment and keep as a spare.

While it was in bits I decided to improve the breathing on the casing, had a -10 to -6 fitting so drilled the centre out to -10 and drilled and tapped the box. Amazing how small the original breather hole is on the F23. That fitting will have a pipe going up and into the breather tank.

All together and zinc painted to make it pretty. Will get it bolted back to the engine and that can go back into the car now.

|

anthcorsa

Member

Registered: 18th May 07

Location: Middlesbrough

User status: Offline

|

Amazing work. That gearbox looks awesome

|

Jed D

Member

Registered: 15th Mar 11

Location: Durham

User status: Offline

|

just checking in, great work as always mate

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Cheers guys appreciate it

|

tom_simes

Show Staff

Organiser: South Wales

Premium Member

Registered: 12th Jan 05

Registered: 12th Jan 05

Location: Undy, Newport Drives: Skoda Octavia vRS estate

User status: Offline

|

Just read the whole lot, including the bit where 'this is a daily, no engine mods'

Cracking build, and was trying to work out where you worked - couldn't tell if it was Bovington, but the workshop didn't look too familiar!

Just one question on the tube bender - does the MSA blue book talk about necking of the tubes on the bends? I recall from when I did Formula Student about 10 years ago, necking was a big no-no, and would fail scrutineering. It needed to be mandrel bent.

|

davegreen

Premium Member

Registered: 20th May 12

Registered: 20th May 12

Location: Oxfordshire

User status: Offline

|

coming together nicely

must find time to rework my F23 ready for the corsa

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

quote:

Originally posted by tom_simes

Just read the whole lot, including the bit where 'this is a daily, no engine mods'

Cracking build, and was trying to work out where you worked - couldn't tell if it was Bovington, but the workshop didn't look too familiar!

Just one question on the tube bender - does the MSA blue book talk about necking of the tubes on the bends? I recall from when I did Formula Student about 10 years ago, necking was a big no-no, and would fail scrutineering. It needed to be mandrel bent.

Erm yeah that part never goes to plan does it

Cheers, I'm based at Poole as the Metalsmith but know a few lads at bovi.

To quote the msa blue book: 1.4.3. The tubing must be bent by a cold working process and the centreline bend radius must be at least three times the tube diameter. If the tubing is ovalised during bending, the ratio of minor to major diameter must be 0.9 or greater.

The bends from the bender I have barely oval the tube at all and are well within there tolerance set by the msa thankfully

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

quote:

Originally posted by davegreen

coming together nicely

must find time to rework my F23 ready for the corsa

Cheers Dave/Ambrose

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Well the couple of quite weeks at work didn't go to plan and in fact turned into the busiest I've had since being there so hardly got anytime for the car.

I did a light swap back to standard but decided tint the indicator and reverse lights as was never a fan

Swapped my pulley on the charger to a slightly smaller one, used run 9psi so it should now run 12-13psi so should help to lean the massively rich map out at WOT as it's currently in the 10's and I'd much prefer it in the high 11's to 12 dead. I plan to fit an adjustable fpr to help fine tune if needed.

Also finally got the engine back in the car and off the axle stands, will get it plumbed and wired up when I get some time.

The stiffened engine and gearbox mounts were obvious as it made it harder to line the bolts up but to rock the engine there is no movement so hopefully make a noticeable difference

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

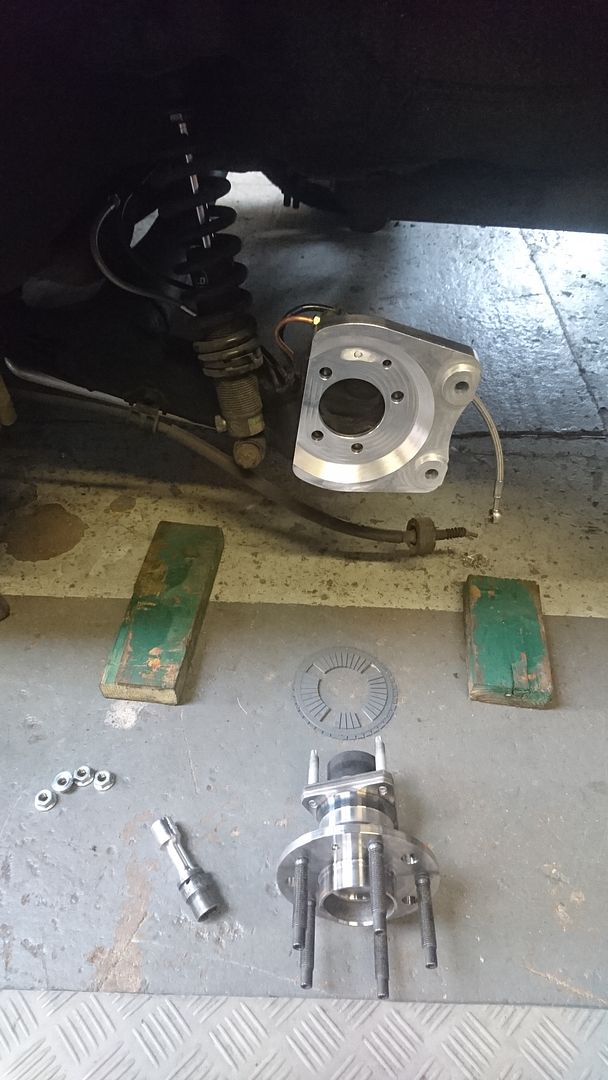

Back off summer leave so got back to doing the car. Made a start on the rear end geo and brakes.

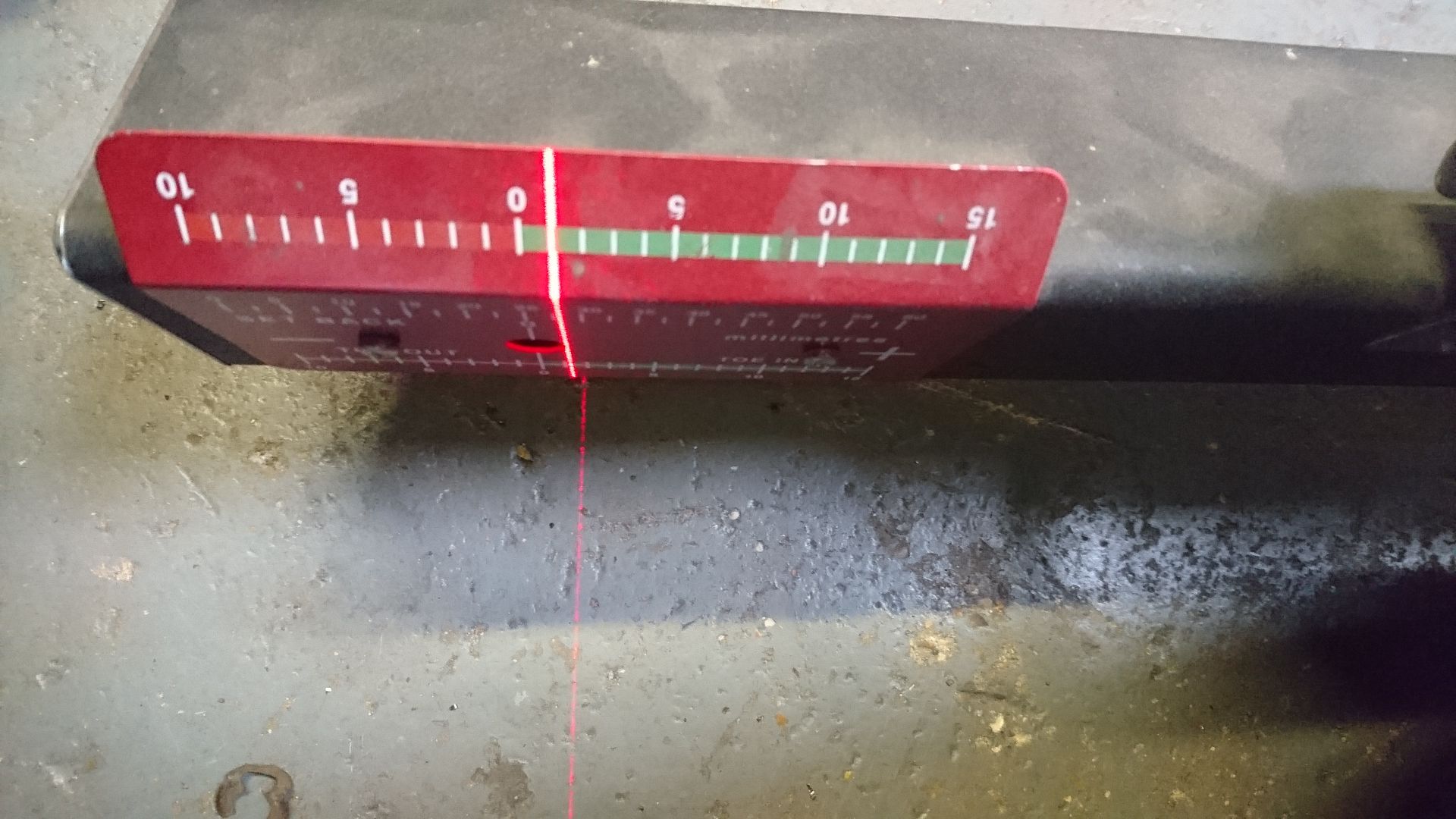

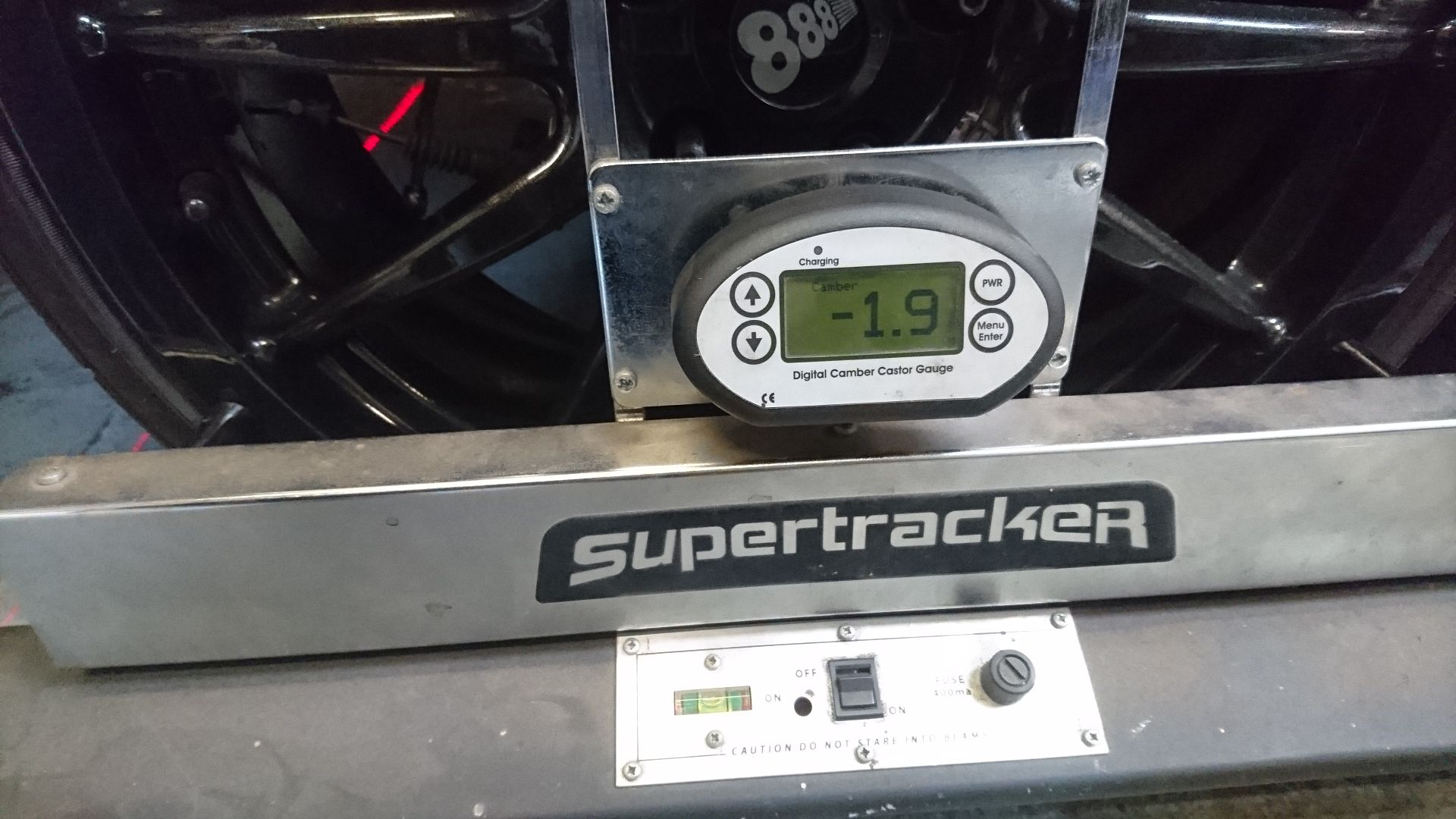

After initial measurements on beam and a lot of mental arthimatic I realise I could only get the beam so close with my camber and toe setting as they only do +&- 1.5 degree changes so after much swearing and what must of been hub wheel and hub off about 50 times a side I got it sorted by using some shimming metal I had, used 0.020" on passenger side and 0.005" on drivers to get me my final even goal.

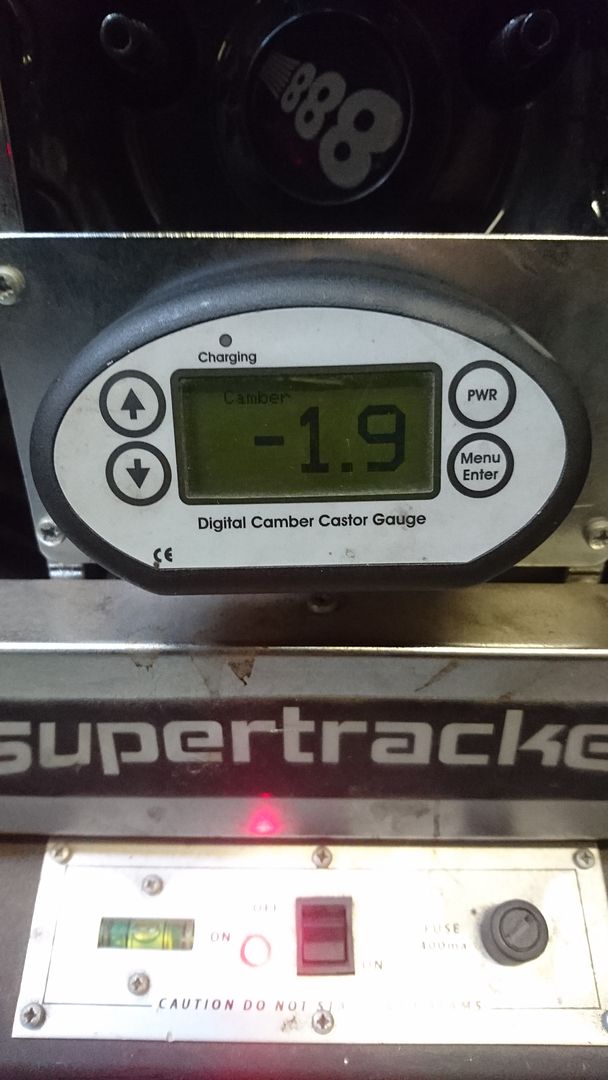

After a good chat with Max Coates (clio cup race winning and ex btcc driver) who helps out as driver coach at the Armed forces race challenge (AFRC) he and some of the engineers recommended i go for a toe out setting instead of the toe in I previously had planned. So I aimed for 1mm toe out each side and pre lowering of -2 degrees camber. I managed to get the toe spot on and the camber just 0.1 degree off. Once final ride height is set that should drop to my ideal figure of -2.5 degrees.

Really not a fan of the plastic shims as once torqued up they deform so the metal shims are the way forward

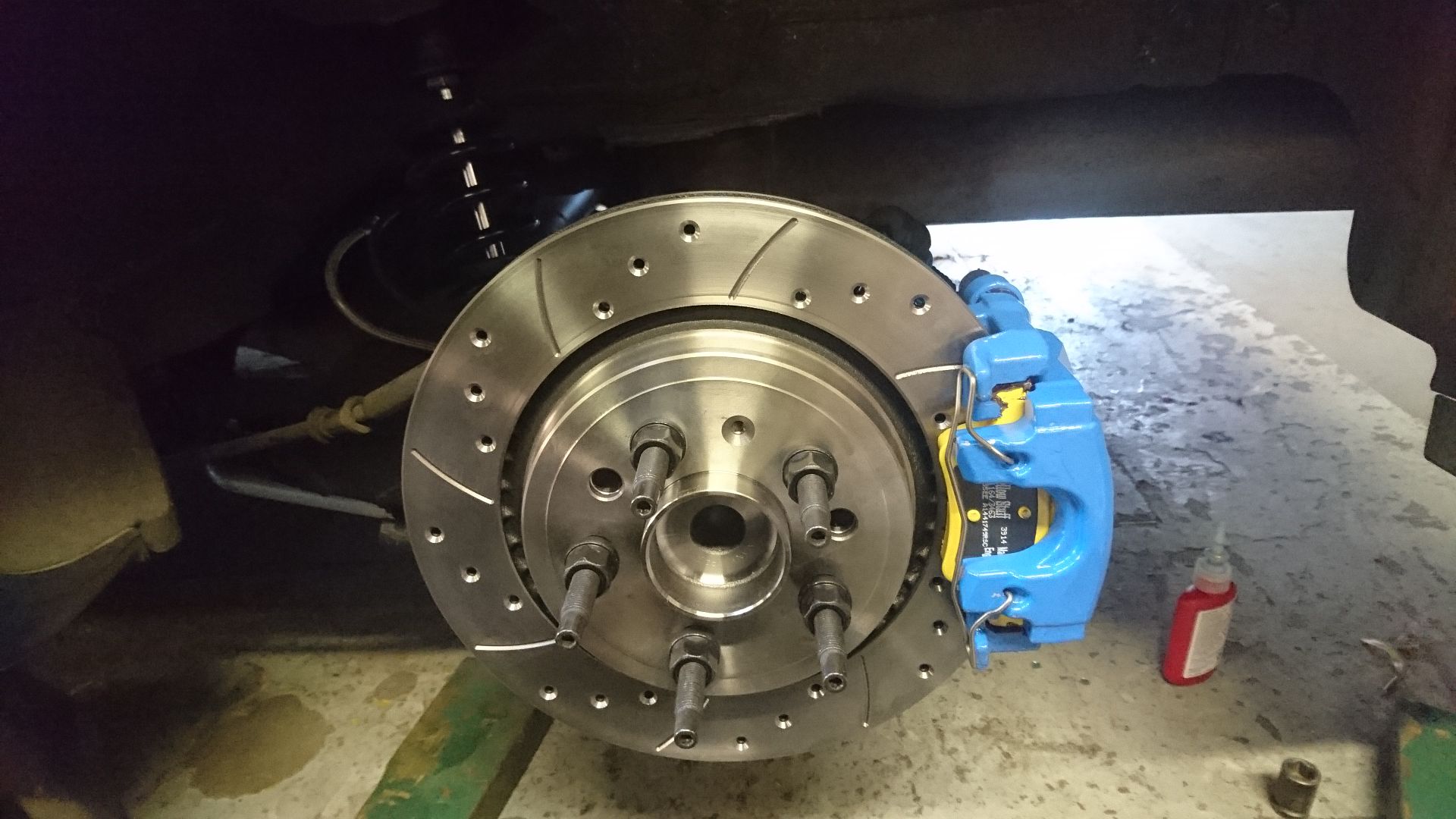

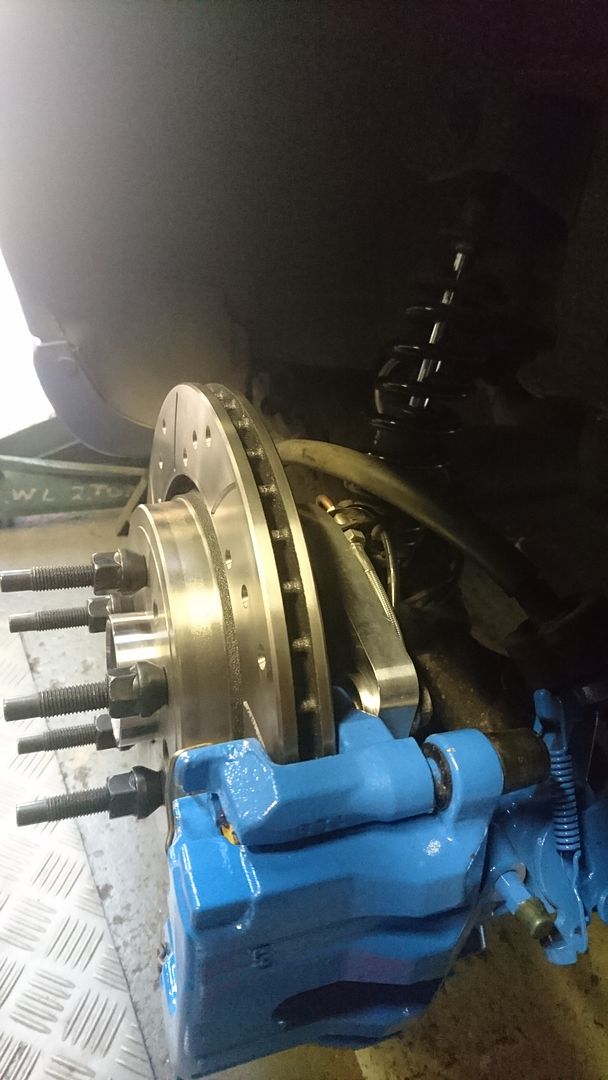

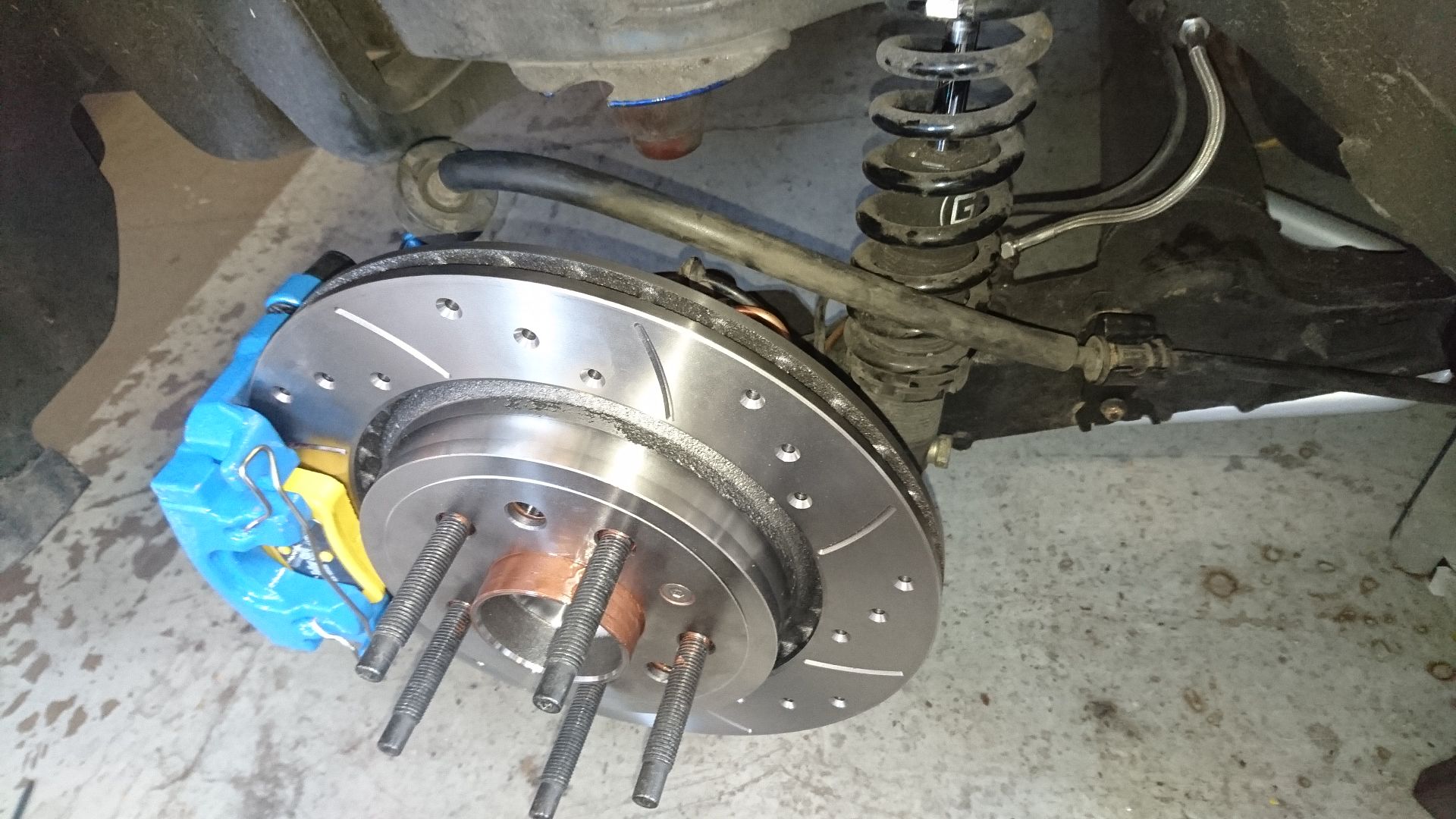

Once that was finally done it was time to fit the vectra c vxr rear ventilated discs (291x20mm) and calipers with yellowstuff pads. Had to shim the caliper over allow for the thickness of the camber/toe shims.

Just need to make new handbrake cable support brackets and buy new bango bolts (came with the wrong pitch thread) and that's the rear all done.

|

boylers11

Member

Registered: 27th Jul 06

Location: Shropshire

User status: Offline

|

I've said it before, but an amazing project.

Attention to detail is second to none!

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

quote:

Originally posted by boylers11

I've said it before, but an amazing project.

Attention to detail is second to none!

Cheers mate really appreciated, hopefully it will pay off and be a very good race car

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Finished the brakes off today, just need a bleed. Modified the handbrake bracket to support it in its new higher position and keep it away from the wheel and spring.

Fitted the dry wheels to check for clearances to arch and all is fine just needs a final ride height setting (pre corner weighting)

|

sxibeast

Member

Registered: 6th Aug 03

Location: Milton Keynes

User status: Offline

|

Brilliant build mate!

|

djgritt

Premium Member

Registered: 1st Nov 07

Registered: 1st Nov 07

Location: Dorset Drives: Focus ST / Hyundai i20N

User status: Offline

|

Coming along really well now.

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

Thanks a lot, it's getting there slowly

|

dewismotorsport

Member

Registered: 16th Feb 08

Location: Coventry & Poole

User status: Offline

|

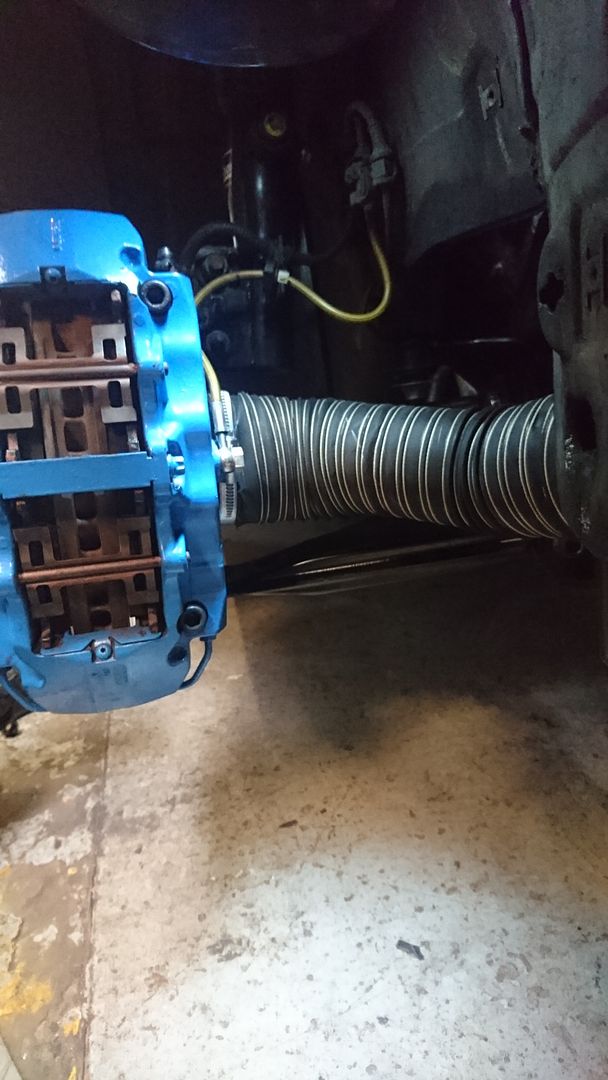

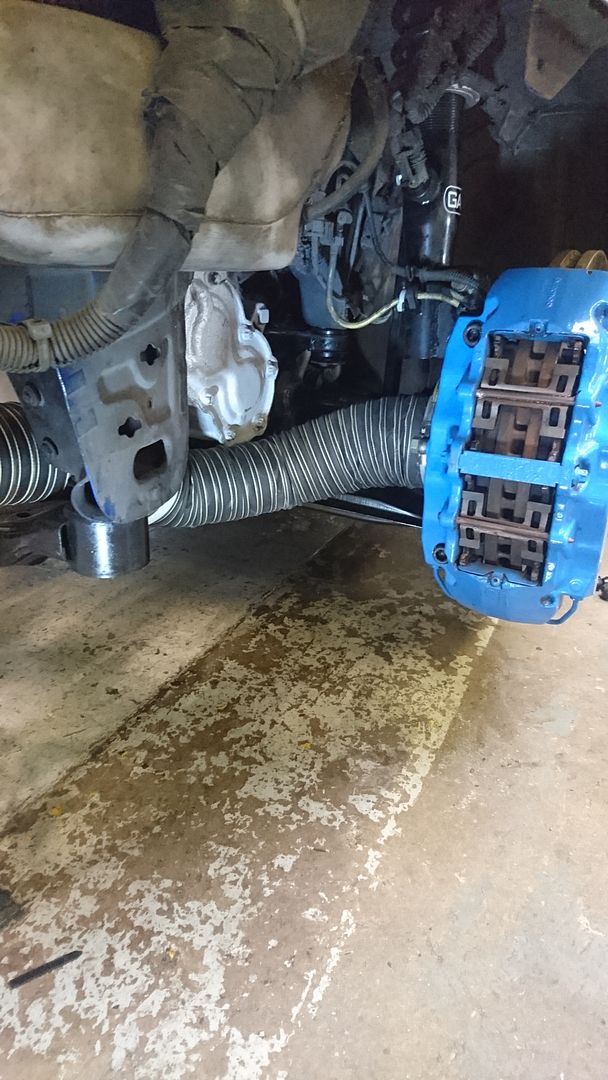

Been cracking on, brakes all bleed up and handbrake set. Driveshafts re fitted but then noticed an error I'd made with the brake ducts, on full lock they fouled the cv gaiter and shaft, so chopped them down and squished them and all was good. Also had to remove the metal wire and threads from end part of the hose as it wouldn't go over the duct.

All fitted

New lubes arrived so topped it back up

Old cheap air filters ready for the bin, had a spare ITG filter so going to use that, the size difference is comical, just waiting for a 4" to 3" reducer to turn up.

Semi slick wheels have gone on so treated the wets to some bags, have handy carry handles and we're only about £10 for 4 so rude not too

Made a start mocking up the intercooler pipe work, had some pipes left over from the corsa so used them as a guide. I've toyed with modding the intercooler to have both inlet and outlet on the same side to help shorted the pipe run but I will try it this way for now as both ways will be tight on space.

Pretty much the same style pipe from this side too

Just waiting for new silicones to arrive but I can now make a start on chopping up the inlet to convert it to air to air rather the charge cooler system.

|