Nath

Member

Registered: 3rd Apr 02

Location: MK

User status: Offline

|

quote:

Originally posted by ed

What exactly do you think the rivets are doing there though?

This is my thinking also.

|

ed

Member

Registered: 10th Sep 03

User status: Offline

|

The original Comet had windows that were fitted only using mechanical fastenings as the manufacturers couldn't bond the windows in for whatever reason. That coupled with an insufficient corner radius on the windows lead to the thing falling the pieces under very low loading. The Nimrod bears very little structural resemblance to the Comet.

|

ianofbhills

Member

Registered: 10th Feb 01

Location: newcastle

User status: Offline

|

re:comet- fair enough i dont proclaim to know much about that subject.

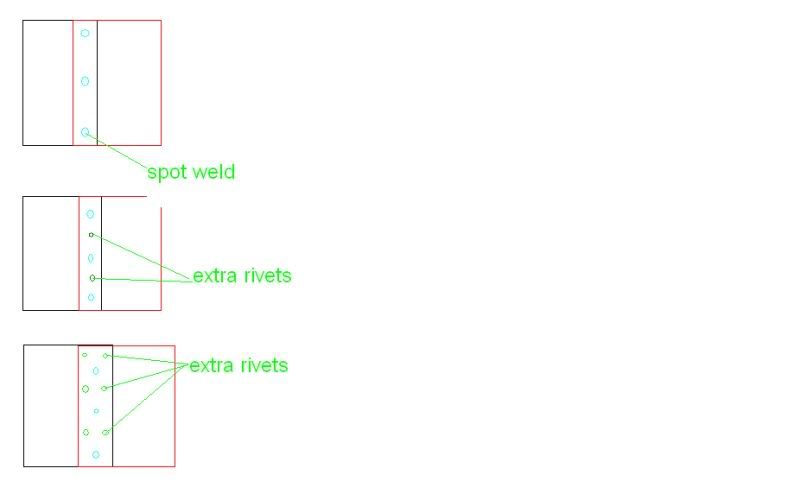

Excuse my hurried ms paint diagram  This is my understanding what do you think? This is my understanding what do you think?

Take an ordinary lap joint the top diagram is as per manufacturer with just spot welds holding the two pieces of metal together.

number two has additional rivets added

number three has more rivets added.

which one makes the strongest joint?

[Edited on 07-09-2010 by ianofbhills]

|

ianofbhills

Member

Registered: 10th Feb 01

Location: newcastle

User status: Offline

|

(obviously number four diagram as per the skyline front struts would be swiss cheese with far too many rivets and not enough material left)

|

ed

Member

Registered: 10th Sep 03

User status: Offline

|

The spot weld. Why would you even bother putting rivets in there if you were welding it? If you were to tensile test the joint, I'd put money on the force at the moment of failure being so great when the weld failed it would simply destroy the pop rivets. The holes drilled for the pop rivets would possibly even cause the riveted joints to fail before the joint with only welds.

Of course, for a joint like that, the most superior way to join the materials would be adhesive.

|

3CorsaMeal

Member

Registered: 11th Apr 02

User status: Offline

|

should of just made most of the car from P38 filler really

|