Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Well I keep getting people asking whats going on with my car etc so I thought it would be a good idea to keep people posted with what I currently upto etc.....

I'll keep this going with other cars too!!

Doing more work on this car at present

Plans:

Large port head

New gearbox with upgraded internals ( blown 3rd gear at combe  ) )

New Hybrid ko3s (with RS6 wheel - already a hybrid with larger wheel etc)

Spec of car at present:

Engine

1.8 20VT (AYP)

Turbo Dynamics MD445 Hybrid K03S

Jetex FC-08001 conical filter (with 102mm CAI in wing)

Custom turbo intake pipe

LCR (3") MAF housing with standard Ibiza Cupra element

LCR (4 bar) fuel pump

BAM 386cc injectors

JBS K03x cast exhaust manifold

Devil's Own Stage 2 water methanol injection

Badger5 custom stage 3 remap

Zeitronix ZT-2 Wideband controller with Bosch LSU-4 sensor

Blueflame bespoke turbo-back exhaust with 200 cell race cat

Forge Motorsport 007P diverter valve (relocated to cold side)

Forge Motorsport UNOS manual boost controller

NGK BKR7E spark plugs

Forge Motorsport black silicone vacuum and coolant hoses

Mocal braided fuel lines

Neuspeed short shifter

Backdraft Motorsport baffled sump

Phenolic 10mm insulator intake manifold gasket

Saikou Michi 951 catch tank

Removed/resistored N112/N249, SAI, PCV and EVAP

Pro Alloy bespoke FMIC with custom 2.5" mandrel bent ali pipework

Vibra-Technics Race front and Fast-Road rear/gear box engine mounts

Integrated Engineering forged connecting rods (with Calico big end bearings)

Odyssey Extreme Racing 25 battery located in spare wheel well

OE washer bottle replaced with 1.2L bottle (hidden in front bumper)

Inlet manifold, strut brace and rocker cover resprayed anthracite

034 Motorsport carbon fibre coil cover

ECS Tuning carbon fibre intake manifold cover

Transmission/Drivetrain

Peloquin 02J ATB differential

Helix 6 paddle clutch and lightened (6.5KG) single mass flywheel

Handling/Suspension

KW Variant 1 coilovers (with replacement top mounts and bearings)

Vibra-Technics front wishbone rear bushes and OE replacement front bushes

Neuspeed 25mm/28mm front and rear anti-roll bars

OMP front lower strut brace (Golf MK2 fitment)

SEAT Sport (MOMO) front upper strut brace

RaidHP rear upper strut brace (MK1 Golf GTi fitment)

Vibra-Technics rear beam bushes

FK 5mm/20mm front and rear hub centric spacers

Brakes

HiSpec R114-4 (4 pot) radial mount calipers

310mm x 28mm two-piece grooved front discs with anodised ali bells

Ferodo DS3000 front pads, stock rear

Braided front hoses

Motul RBF 600 brake fluid

Wheels and tyres

Winter use: OE Cupra alloys powdercoated anthracite, wrapped in 195/45/16 Uniroyal Rainsport 2s

Summer/track use: Compomotive MO 5 alloys powdercoated anthracite

Exterior

LiteTuned carbon fibre bonnet

De-badged/de-wipered bootlid

Tinted windows

LCR splitter

Osram Diadem indicator bulbs

LED sidelights & number plate lights

6000k HIDS

Front retro-fit aero wipers

ROB813 C private plate

Interior & ICE

Autogauge mechanical boost gauge housed in Nomad Racing A-pillar pod

VEI Oil Temperature/Pressure dual gauge

VEI AFR wideband gauge (both housed in Cupra R holder)

Flamebeater 0.6KG powder car extinguisher

SEAT Sport tax disc holder

Infinity 6520CS components

MD445 Hybrid turbo specification:

K04 turbo with Hi flow K04 compressor wheel, cnc machined compressor housing , large

trim K04 turbine wheel, lightening of turbine wheel for faster ‘spool up’, cnc modified

turbine housing, ported wastegate, uprated turbine seals. Other ‘blueprinting’

modifications. 12 psi Uprated actuator. Rated to APPROX 280-300 BHP

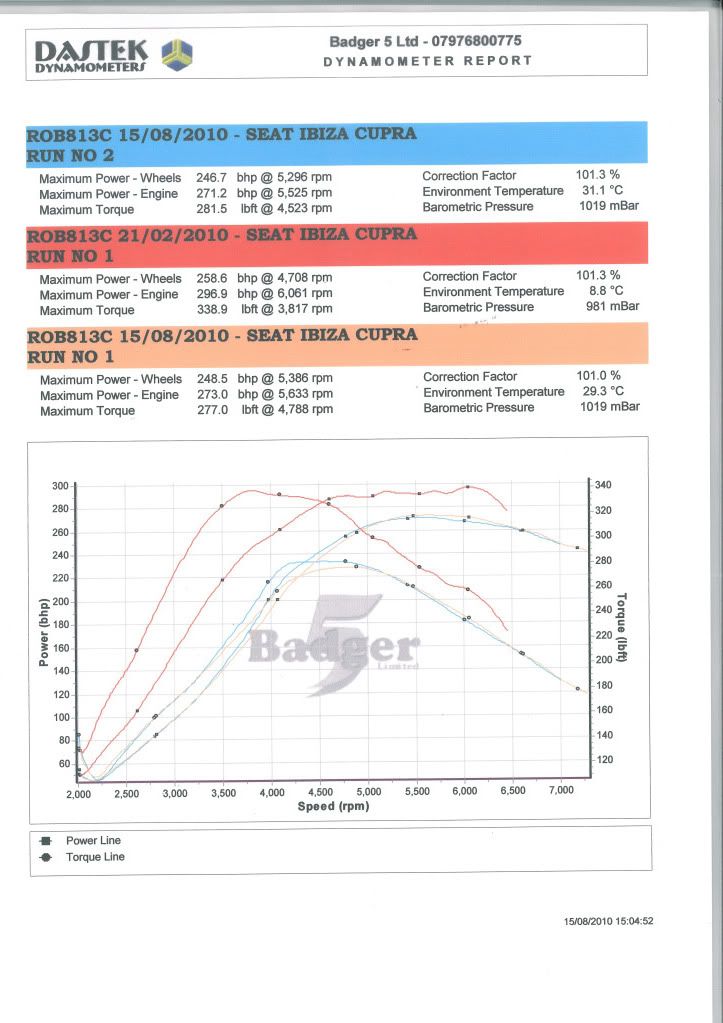

Click here for latest RR graphs. 279 BHP, 281.5 lb/ft

Here is the project thread of the whole car Robbie C's MK3 Ibiza Cupra Hybrid K03S build - SEAT Cupra.net - SEAT Forum

I done 99% of the work on this car since it was bought standard

Started the strip down, Removing bumper etc

Intercooler etc removed

Will be carrying on tomorrow night

Dale

|

mike56gte

Member

Registered: 23rd Jun 09

Location: Fife, scotland Drives: Audi S3

User status: Offline

|

|

K2NY-G

Member

Registered: 6th Feb 08

Location: Fife, Scotland

User status: Offline

|

Nice build, i had the same spec on my old one

|

antnee

Member

Registered: 30th Dec 07

Location: Cov Drives: Clio 197

User status: Offline

|

Is that JBS manifold one of the old ones? Still holding up alright with no cracking?

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Cheers guys

quote:

Originally posted by antnee

Is that JBS manifold one of the old ones? Still holding up alright with no cracking?

When we first started it was an "old" JBS one but it wouldn't fit since they repair it  (warped Flange etc) Then we went for a INA cast version (which ran ok but was a shite design tbh and now alot of people have had them crack) while JBS designed the new manifold, they stated once the manifold were built Rob could swap the old JBS for a new one! We then fitted the New style JBS manifold and have ran this for 4,000-5,000 miles without a problem or signs of cracking.... So far all good (warped Flange etc) Then we went for a INA cast version (which ran ok but was a shite design tbh and now alot of people have had them crack) while JBS designed the new manifold, they stated once the manifold were built Rob could swap the old JBS for a new one! We then fitted the New style JBS manifold and have ran this for 4,000-5,000 miles without a problem or signs of cracking.... So far all good

|

AndyCorsaSport

Member

Registered: 12th Feb 06

Location: Horsforth, West Yorkshire

User status: Offline

|

Are you stripping it down for a bigger spec?

|

Graham88

Member

Registered: 16th Apr 07

Location: South East Kent Drives: E46 M3

User status: Offline

|

Good stuff. That mods list is bloody impressive.

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

quote:

Originally posted by AndyCorsaSport

Are you stripping it down for a bigger spec?

Yer its having a large ported head fitted (Valve stem seals going on present head), SQS synchro gearbox and the last stage hybrid K03 making it a K03-2283 which has a RS6 compressor wheel (This is is going to be one of the first cars for this turbo) fitted to it would should put it over 300 mark

quote:

Originally posted by Graham88

Good stuff. That mods list is bloody impressive.

It is indeed alot of work has gone into this  I remember when it turned at mine standard!! I remember when it turned at mine standard!!

Little update again, Nothing really interesting

Turbo to cooler setup removed

JBS manifold.... hasn't cracked yet

Engine nearly ready to come out apart form pas pipes...

Free to a good home

Dale

|

antnee

Member

Registered: 30th Dec 07

Location: Cov Drives: Clio 197

User status: Offline

|

Thats good about the manifold then! I know Ian (ian_cupra on SCN, also a blue Mk3) had shed loads of problems with JBS, took them about 2 years to sort the manifold out for him.

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

quote:

Originally posted by antnee

Thats good about the manifold then! I know Ian (ian_cupra on SCN, also a blue Mk3) had shed loads of problems with JBS, took them about 2 years to sort the manifold out for him.

Yer rob did have loads of problem with them too but they did supply the new item and it's been good since! But when it fails the arguing will start again! Shame it has to be like this tho

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Little Update on Robs baby:

First off to finish getting the engine out

And its out

Empty

Complete

Box off + Clutch off

Helix Clutch going well 7,000 roughly since Alex fitted it

Flywheel off and on the stand

Split the Gearbox to remove Robs diff for his new one  I found this... I found this...

Lots of bits and well someones taken the teeth clean off!!

Dale

|

Graham88

Member

Registered: 16th Apr 07

Location: South East Kent Drives: E46 M3

User status: Offline

|

NICE! Proper job

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Late update on the cupra  been so busy been so busy

anyway time for head to come off, strip down:

Rocker cover off

all timed up and tensioner pin in

Next time to take JBS manifold off :censored: Spanners i used with slight modification

The blown gasket from manifold to turbo

I took the cams out with the head still bolted on, First marked the chain and gears and fitted the chain tensioner tool

Then head off and stripped of small parts ready to send away for porting etc

Thats all for now Dale

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Well robs not had alot of luck with his engine

I copied this from his post....

Cheers Dale.

Following on from this latest work there's a bit of a twist in the tale, resulting in a major change of plans for the immediate future at least.

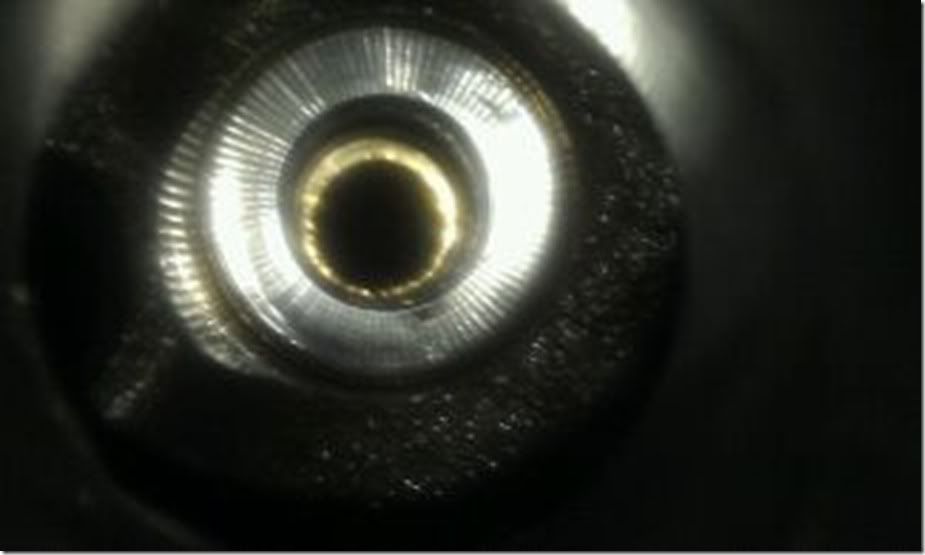

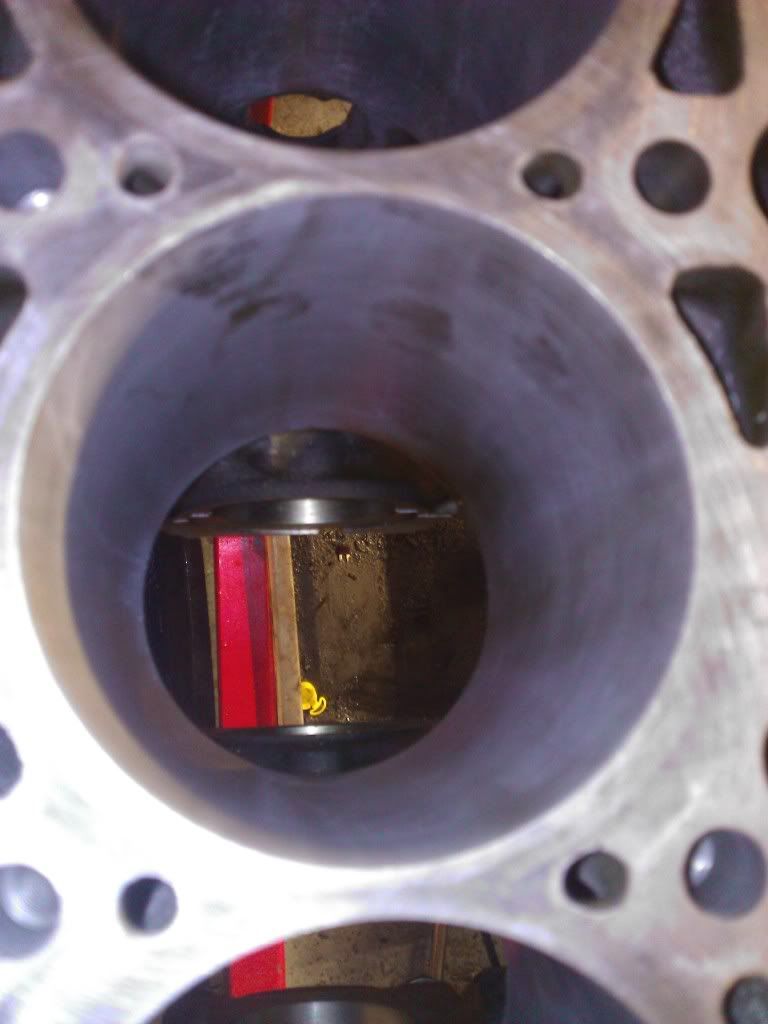

Upon removing the cylinder head and inspecting the block there's very evident scoring in each cylinder bore, most notably #1 (which receives the most air). The worst marks can be felt with your nail - not your average wear and tear.

Cylinder 1:

Cylinder 2:

Cylinder 3:

Cylinder 4:

Back when Bill fitted my uprated rods in Dec 2009 he noted that there were signs of scoring, but nothing as bad as what we see here, some 7,000 miles since.

While it's open to speculation what could have caused this it's most likely either:

1. Debris entering the intake

2. Worn rings causing piston slap

I am curious as to whether I may have damaged my rings when my WMI unknowingly stopped working and the car was still driven hard on boost, causing sky high CFs. This is one possible theory of many, who knows...

Upon removing the pistons tonight there are no signs of any damage to the crown, but the skirts do have some form of debris stuck to the sides which would seem to account for the scoring. Whether these are melted fragments of piston ring is unknown.

I noticed some time ago that I was also consuming some oil that appeared to be being burned (no signs of any leaks), though a compression and leak down test suggested that compression was OK (see here)

It's difficult to know what's really responsible here when these tests show healthy figures, not forgetting the car itself was driving and performing perfectly well prior to the gearbox and manifold issue at Castle Combe.

So, from here I've decided to re-focus my efforts on completely re-building the engine to it's fullest potential, with:

Overbore to 82.5mm (retaining standard head gasket)

JE 9:1 2618 alloy pistons

Port/polished head by JNL, fitted with Supe***** valve guides, stem seals, inconel valves and valve springs/titanium retainer set

New main bearings and supporting bolts/caps as required

As I'm already running IE forged con rods this will give me a fully built engine, that together with my SQS gearbox ought to be pretty bullet proof and ensure I don't have to go to the effort and expense of stripping anything down for upgrade again. Do it once, do it properly.

Once this is all sorted I will re-assess my turbo options as and when I feel it necessary, which also allows more R&D time on the new breed of K03-2283 hybrids currently in development/testing by the likes of Badger5.

Continued thanks to Alex, Bill and Dale for their help and support - appreciate everyone's input.

More pics and progress reports to follow soon, with the aim of sending the head and block away this weekend to begin the necessary work.

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Well since my last post robs sorted out what he wants to do next with the engine (see above) so on to engine strip ready for block work

First off loom and all bolt on parts off

Flip it over ready for pistons etc to be removed

Oil pump off and pistons out

Pistons (Left is 4, right is 1)

Hard to see but this is cylinder 1 with scoring all down the piston on both sides inlet and exhaust (above and below the rings)

Cylinder 3 scoring all the way to the bottom of the stroke ( Battery died on camera to take anymore pictures )

And the crank bolt beat my trusty adaptor

Another socket later and crank was out etc

All main shells were fine and no signs of excessive wear

Thats all for now

Dale

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Really late but big update

Well the cause of engine damage was found to be valve guides

So lots of new bits  Copied from seat cupra forum Copied from seat cupra forum

This afternoon my JE pistons, ARP main studs and Ferrea valvetrain arrived from the US - big thanks to Sam @ INA for the service on this order, much appreciated.

It was like Christmas had come early when these bad boys arrived on my doorstep:

This evening I then took these over to Alex @ Backdraft ready to gap the rings and allow JNL to finish rebuilding my ported/polished AYP head, which has now also had a full new set of intake guides fitted following our recent findings - let's hope that's the last of it.

My block has now also been overbored to 82.5mm (1847cc) ready for my new JE pistons (9:1 CR) so it's all starting to come together.

On top of that I also took collection of my uprated SQS gearbox, running the SSS (street strong) semi-helical gears which look pretty damn chunky.

This weekend the head and block should be finished, ready to pick up and start putting everything back together to make a car again, now I've also got hold of my sputter big end bearings, thrust washers, main bearings, head bolts and all necessary gaskets. Big thanks to Alex for helping me get this sorted and giving up his time this evening, really appreciate it.

It's getting there, watch this space

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

I've now picked up my overbored block and ported/polished head which means we've now got everything needed to get it back in one piece again. Dale will be making a start later this week, starting with a lick of VHT satin/matt black paint on the block

Few pics:

Fully built ported/polished cylinder head back from JNL:

Overbored block:

Cylinder 1:

Cylinder 2:

Cylinder 3:

Cylinder 4:

new JE pistons alongside my IE rods

We've also taken delivery of most of the final bits and pieces needed to make a complete car again, including new oil pump, metal impellor water pump, OE cambelt kit (w/ tensioner), 10 litres of Millers 10w40 Competition Running In mineral oil and 10 litres of Silkolene/FUCHS Pro-S

All being well the engine ought to be built back up over the bank holiday weekend, pretty much ready to slot back into place next week.

Very very late reply and this will keep rob happy  On to the car then.... On to the car then....

After picking everything up from Alex @ backdraft it was rebuild time, alex has cut each piston ring to each cylinder as below

Installing rings to the JE pistons

Then it was time to introduce the IE conrods to the JE's (Sad i know  ) )

The block was rubbed down and as much surface rust removed as possible, then through the parts washer at work, once this was done it was painted in high temperature satin black block paint.

Then the crank was cleaned out in the parts washer ( Everything has been cleaned and double cleaned due to the wear on the valve guides )

More to follow

Fitting ARP Main studs + nuts. Cleaned everything as usual...

Studs + main shells installed

Crank installed and all torqued down

Piston and conrods were installed next with new big end bearings and arp 2000 bolts

New Genuine oil pump was installed including associated parts

Next was the sump adjustment due to the arp main stud and nut height difference over bolts ( A Few pictures to help people out )

Sump placed on

The gap at the gearbox end

The two lugs that require removal

After removal

Rear crank seal was then installed before sump was sealed and bolted on!

Metal impeller water pump and new cambelt tensioner was installed

Head gasket installed

Head was then torqued down

Few Pictures of the head installed

Engine all timed up with new cambelt, tensioner and roller

And where I'm upto, waiting for a few last gaskets which should be here tomorrow

While waiting for the gaskets, I've measured up some bolts to solve robs engine mount bolts "vibrating loose" due to the harder engine mounts and the use it gets, which i can thread lock and nut on the other side acting like a "locking nut"

The rear gearbox mount has been the main problem  as you can see a bolt has gone for a walk.... as you can see a bolt has gone for a walk....

Plenty of room to use longer bolts with a "locking nut"

I will be doing this to the rear engine mount too

More to follow soon

Dale

|

Graham88

Member

Registered: 16th Apr 07

Location: South East Kent Drives: E46 M3

User status: Offline

|

Good progress!

|

MACKA

Member

Registered: 21st Oct 05

Location: Swindon, Wilts. Drives: Astra GSi & Corsa Sport

User status: Offline

|

Top work as usual Dale. Fancy having a look at my Astra its got an annoying rattle

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

quote:

Originally posted by Graham88

Good progress!

Cheers G its getting there

quote:

Originally posted by MACKA

Top work as usual Dale. Fancy having a look at my Astra its got an annoying rattle

Cheers Ben, Yer drop me a text or something and i'll have a look

More from tonights work

First off had last gaskets delivered at work today....

When we did the build first time we were going to replace the injector seats but never got round to it, so now was a good time to do them...

The tool i used

Old vs new

I then fitted the wiring loom and all coolant pipes inc new thermostat (no photos)

A few inlet ports photos

Refitting the phenolic 10mm insulator (yet to fit top inlet gasket)

Inlet on

|

Dale

Member

Registered: 7th Oct 07

Location: Swindon

User status: Offline

|

Another really really late reply..... Sorry Rob

Anyway heres the last load of pictures

JBS manifold fitted and turbo bolted up

Helix 6 Paddle clutch + flywheel refitted

Engine and SQS gearbox joined together

My little modification to robs engine mounts which should stop them coming out

After Rob came around and cleaned the engine bay

More cleaning

Engine back in..

Front end back on

Intercooler on

All back together

Proof Rob can work (well putting wheels on)

Then it was starting time.... Ran like it was started yesterday......

Ready for me to take to work for MOT and Aircon re-gas

Job done for me  Passed MOT, A/C all sorted and Rob did the first 25miles last thurday (at 14psi) and I changed the oil on friday...... Passed MOT, A/C all sorted and Rob did the first 25miles last thurday (at 14psi) and I changed the oil on friday......

|

Ingham

Banned

Registered: 9th May 08

Location: Burnley, Lancashire

User status: Offline

|

Can't say I've ever liked Ibizas, but this impresses me with the neatness of the bay!

|

Graham88

Member

Registered: 16th Apr 07

Location: South East Kent Drives: E46 M3

User status: Offline

|

Will be interesting to see the thing go...!

|