sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

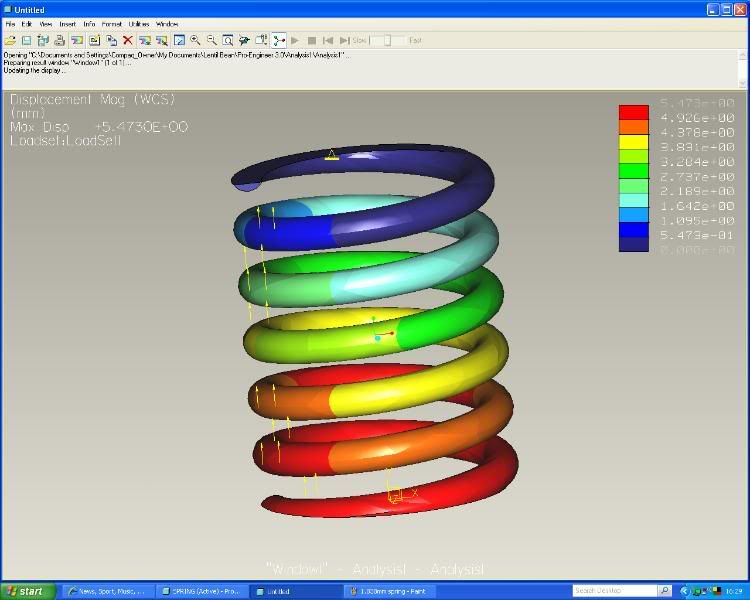

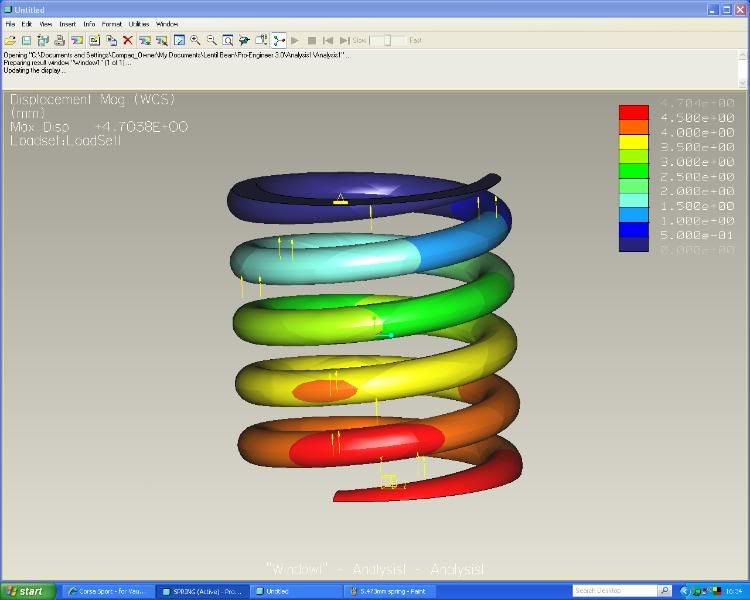

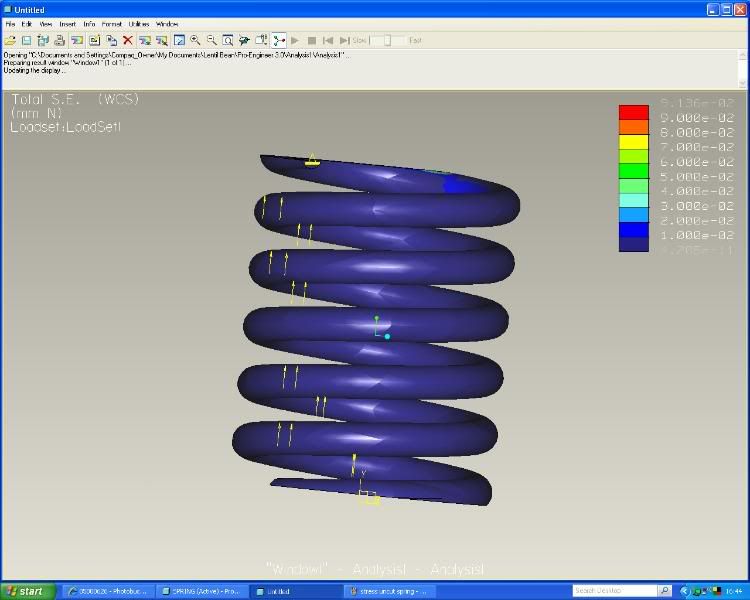

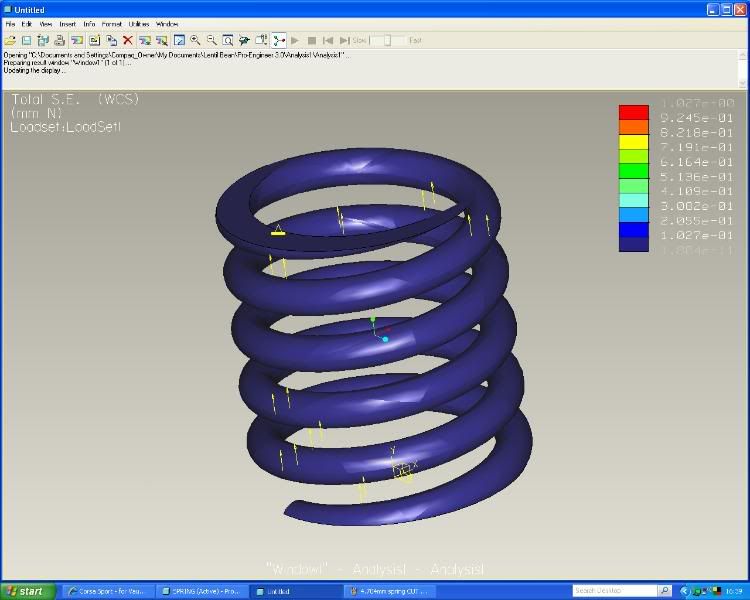

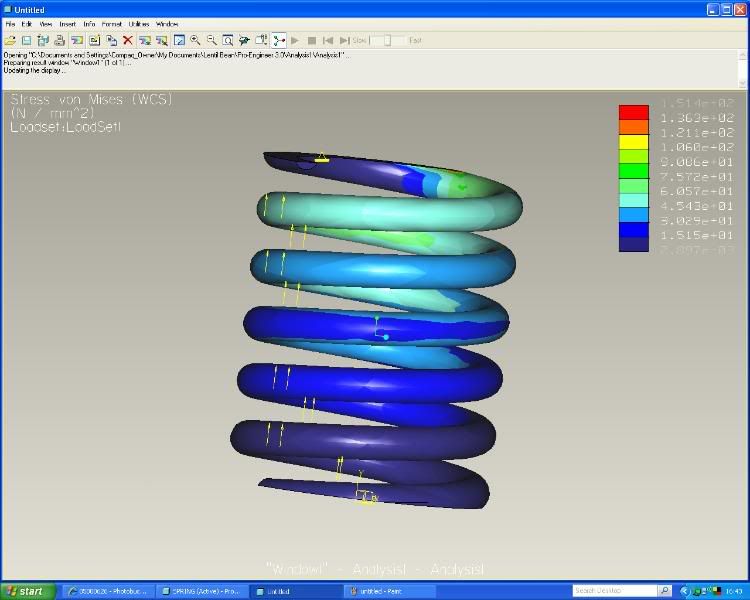

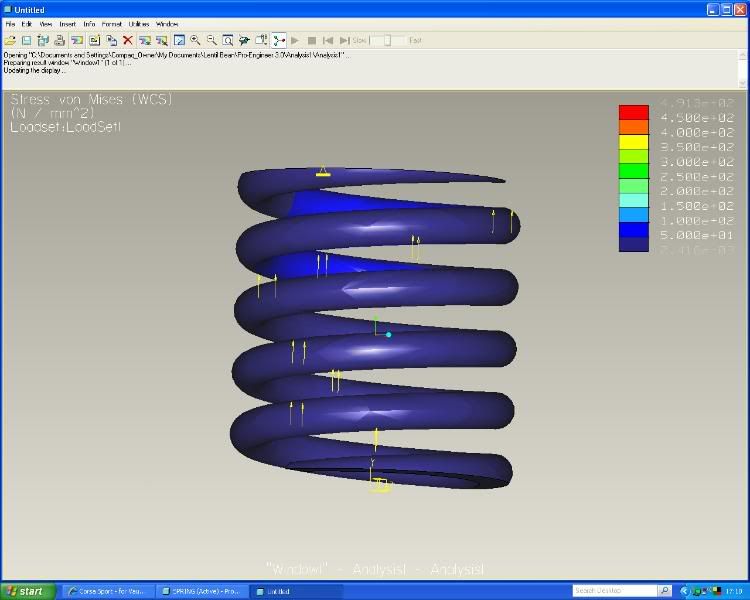

Just done a analysis on two springs very simple ones 300mm and 260mm high both have, pitch 50mm(distance between coils), profile 30mm thick, steel, diameter 200mm. oh yeah and a 2000N load.

Decide for yourselfs if they are a bad idea or not.........

displacement uncut 5.173mm

displacement cut 4.704mm

strain uncut 0.0913 N mm

strain cut 1.077 N mm

stress uncut 151 N/mm^2

stress cut 491 N/mm^2

Well the displacement "movement" decreases on the cut spring so possibly an increase in spring rate.

The strain goes up when cut but is still very low at just over one newton per mm.

Stress on the cut spring goes up alot this happened possibly because when i cut the spring there was a sharp edge somewhere so will not be that high probably around the 350 N/mm^2 mark, this is still low because steel yields "breaks" at around 1000N/mm^2 or more for normal stuff you can get really crap steel at around 300 N/mm^2 but i doubt people would use that on car springs somehow.

[Edited on 10-06-2008 by sand-eel]

|

Colin

Member

Registered: 4th Apr 02

User status: Offline

|

MS Paint

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

Pro-Engineer

|

antoni

Member

Registered: 30th Dec 07

Location: irlam, manchester

User status: Offline

|

i dont get it

|

Archie

Organiser: Scotland

Premium Member

Registered: 18th Dec 07

Location: South Ayrshire

User status: Offline

|

quote:

Originally posted by kangaroojack

i dont get it

x2

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

ok cutting the springs technically should be fine.

|

Sean-B

Member

Registered: 1st May 07

Location: Wolverhampton Drives: 200SX S14a

User status: Offline

|

whoop, did my thread inspire this by any chance?

|

John G

Member

Registered: 18th Jul 05

Location: Wirral, Merseyside

User status: Offline

|

Persoanlly i think your analysis would fall flap on its hoop if you were do it for rear springs.

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

yes.....yes it did

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

quote:

Originally posted by John G

Persoanlly i think your analysis would fall flap on its hoop if you were do it for rear springs.

cutting rear springs are a bad idea though, because of there shape, they won' sit properly anymore.

|

John G

Member

Registered: 18th Jul 05

Location: Wirral, Merseyside

User status: Offline

|

quote:

Originally posted by sand-eel

quote:

Originally posted by John G

Persoanlly i think your analysis would fall flap on its hoop if you were do it for rear springs.

cutting rear springs are a bad idea though, because of there shape, they won' sit properly anymore.

I fear your analysis will only stride people on to continue cutting rear springs, peronally any home bodging of this sort is beyong me!

[Edited on 10-06-2008 by John G]

|

mattyross

Member

Registered: 22nd Dec 05

Location: lincolnshire Drives: 1997 C12NZ

User status: Offline

|

excellent work man

i am a dab hand finite element analysis myself

impressed by this, i like to see practical uses for pro-mechanica

just a suggestion, you could lower the legend value for the stress/strain

|

Ellis

Member

Registered: 11th Sep 07

Location: Aberdeenshire

User status: Offline

|

Whats the conclusion for the rear springs?

Are they likely to fail if cut? At what load?

|

Gareth F

Member

Registered: 16th Jan 08

Location: Location Location

User status: Offline

|

Put me right, always thought it was a bad idea due the spring not sitting properly.

|

ainsley_brader

Member

Registered: 24th Mar 02

Location: Tattershall, Lincolnshire

User status: Offline

|

are corsa springs the same diameter and same distance between coils?

|

mikesc20let

Member

Registered: 13th May 08

Location: nottingham

User status: Offline

|

if your a real tit arse then you can cut the front springs but not the rear as the rears are impossible to cut and get to sit rite but after all the hassle why dont you just buy a second hand kit or just sum properly lowered springs

[Edited on 10-06-2008 by mikesc20let]

|

Brett

Premium Member

Registered: 16th Dec 02

Registered: 16th Dec 02

Location: Manchester

User status: Offline

|

Wow, look how clever you are!

|

Mase

Premium Member

Registered: 16th Sep 01

Registered: 16th Sep 01

Location: Derbyshire

User status: Offline

|

this is my kind of thing!

Pro-mechanica isn't that hard really... only used it briefly mind....

My only concern regarding the analysis is that it cannot take account of any fatigue. I would be concerned about existing fatigue cracks, which would have a tendency to open if loaded with a greater stress, reducing its service life....

Mase

|

mattyross

Member

Registered: 22nd Dec 05

Location: lincolnshire Drives: 1997 C12NZ

User status: Offline

|

quote:

Originally posted by Mase

My only concern regarding the analysis is that it cannot take account of any fatigue.

good point. i think you can set a model for cyclic fatigue, i remember doing it.

good effort sand-eel.

|

RCS

Member

Registered: 26th Jan 05

Location: Lichfield/Dundee

User status: Offline

|

Where does maximum stress occur on the cut spring? And how have you applied the load?

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

The constraint is at the top where the spring sits at the strut top and the load is applied at the bottom where it sits, but it doesn't matter where because it's the same size either way so you could do it opposite and it would be the same.

The maximum stress is at the top where the cut was made, if you smooth out any sharp edges max stress will reduce.

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

quote:

Originally posted by Mase

this is my kind of thing!

Pro-mechanica isn't that hard really... only used it briefly mind....

My only concern regarding the analysis is that it cannot take account of any fatigue. I would be concerned about existing fatigue cracks, which would have a tendency to open if loaded with a greater stress, reducing its service life....

I can do a fatigue test yes....

|

sand-eel

Member

Registered: 15th Mar 07

Location: carluke/braidwood--IRNBRULAND

User status: Offline

|

actually i can't because i need the hardness level for steel......

|